The United States Navy needs help to build submarines which are vital to our nation’s defense. The Accelerated Training in Defense Manufacturing (ATDM) program is designed to quickly train qualified candidates in essential manufacturing skills and trades to establish a steady and sustainable flow of qualified workers for the naval shipbuilding and repair sector of the submarine industrial base (SIB).

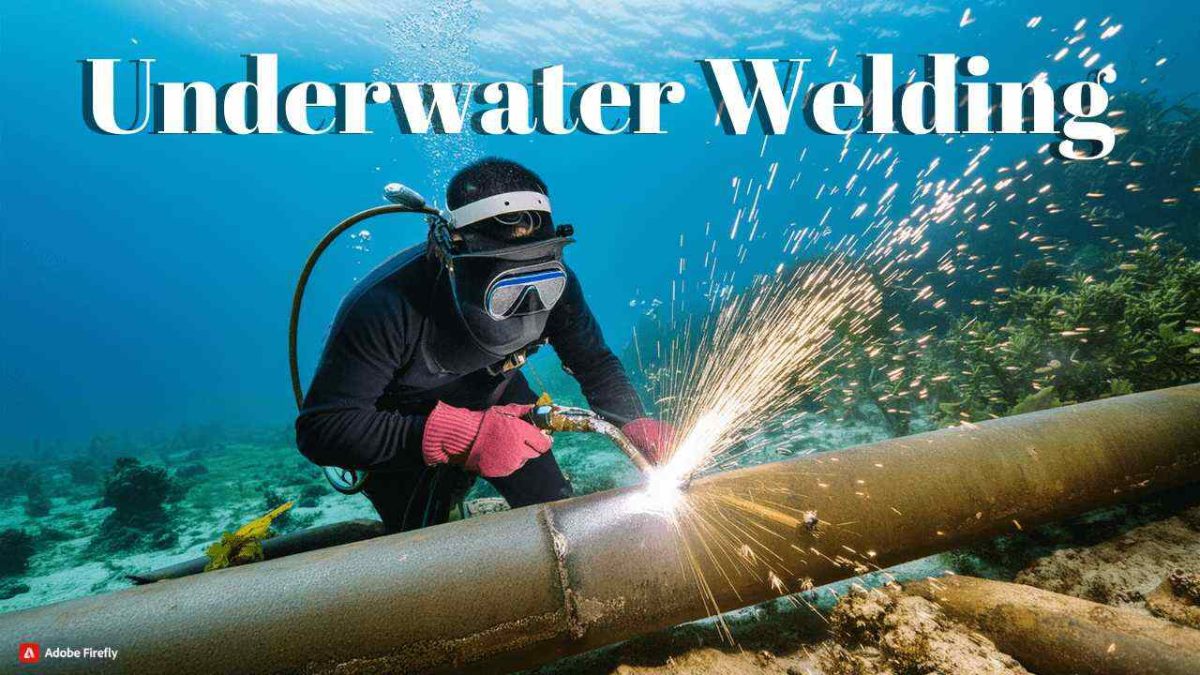

A welder connects metal parts together using a welding rig that melts the metal allowing it to bond together. I wanna be an underwater Welder because I like being hands on and welding metal sounds fun. I also enjoy the water it is also cool.

Some of the things that require Welders is an Oil rig, boats, buildings, cars, submarines, and a lot more including repairing things not just putting them together. The navy needs welders because they are constantly putting something together that requires a welder on site. The demand for this technical skill is not going away; it is only increasing. Because of this , there are many grants and programs that offer payment to be trained and guarantee a job after successful completion of the training.

The annual pay for an underwater welding is 50k-150k. This is the same level of pay a college graduate might expect after 4 years of tuition and full time education. The total cost per year of a Virginia university student is on average $25,000-$38,000. Instead of spending that money and going into debt, a young person like myself can make twice that amont a year as a starting salary in underwater welding. To me that is a great investment.

You can learn the basics from this video.

https://youtu.be/JOV9MNcd02s?si=QRsj08qNlsu4mxk3

- This instructional video was made in Houston Texas

- Under water welders are needed to build oil rigs

- There is wet welding and dry welding underwater